The project's affiliated group is a leading comprehensive pharmaceutical commercial circulation enterprise in China, with business coverage across 28 provinces and over 330 subsidiaries nationwide, ranking in the top three in the domestic industry.

The applying company is a wholly-owned subsidiary of the group, with marketing business covering 18 cities in Henan Province and 17 subsidiaries. Its business scope includes secondary and above medical institutions, primary healthcare, commercial distribution, e-commerce, social retail, and its own chain pharmacies.

With the advent of new medical reforms, pharmaceutical operating companies are facing higher logistics and distribution service standards. To build a modern logistics system, strengthen logistics management, achieve cost reduction and efficiency enhancement, and improve their competitiveness, the pharmaceutical company began to plan and construct a new logistics center and chose Prolog to provide planning, design, and implementation services for the logistics center.

Advanced Equipment and Technology

Achieving Less Waiting, Less Judging, Less Wasting

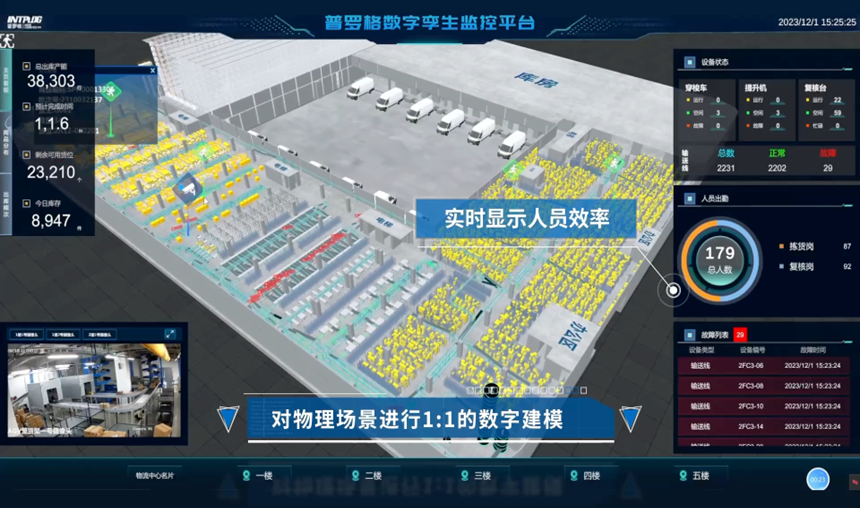

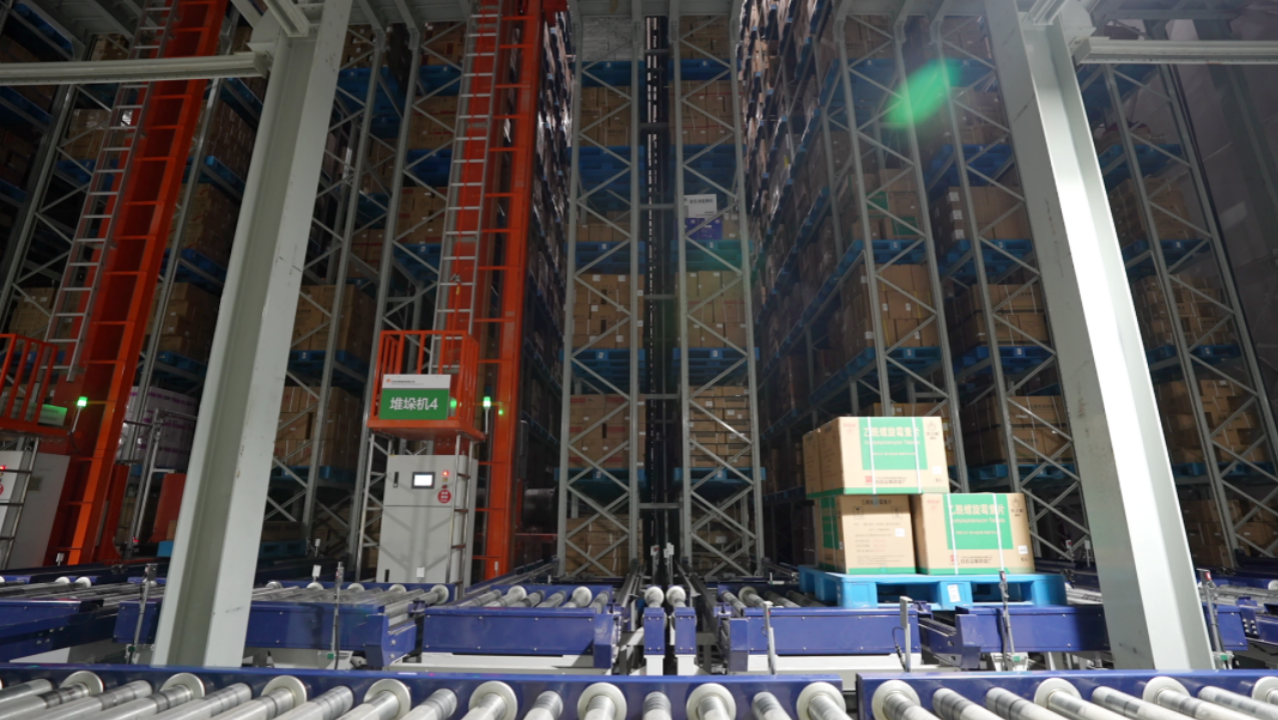

Adhering to the design principle of "less waiting, less judging, less wasting," Prolog has integrated advanced domestic and international logistics facilities and technologies for the pharmaceutical company's logistics center, meeting the integrated functions of goods inbound, storage, sorting, and distribution. The main layout includes storage areas for inbound and outbound goods, AS/RS automated warehouses, shuttle cart automated warehouses, high-bay racking areas, piece picking areas, zero goods re-checking areas, and independent cold storage facilities. Inside the logistics center, high-bay racking, flow racking, panel racking, and pallet ground stacking are mainly used to achieve the storage and picking of full cases and piece goods, while advanced equipment such as conveyor lines, stacker cranes, and shuttle carts are utilized to achieve rapid goods in and out operations.

Save Costs

Higher Space Utilization

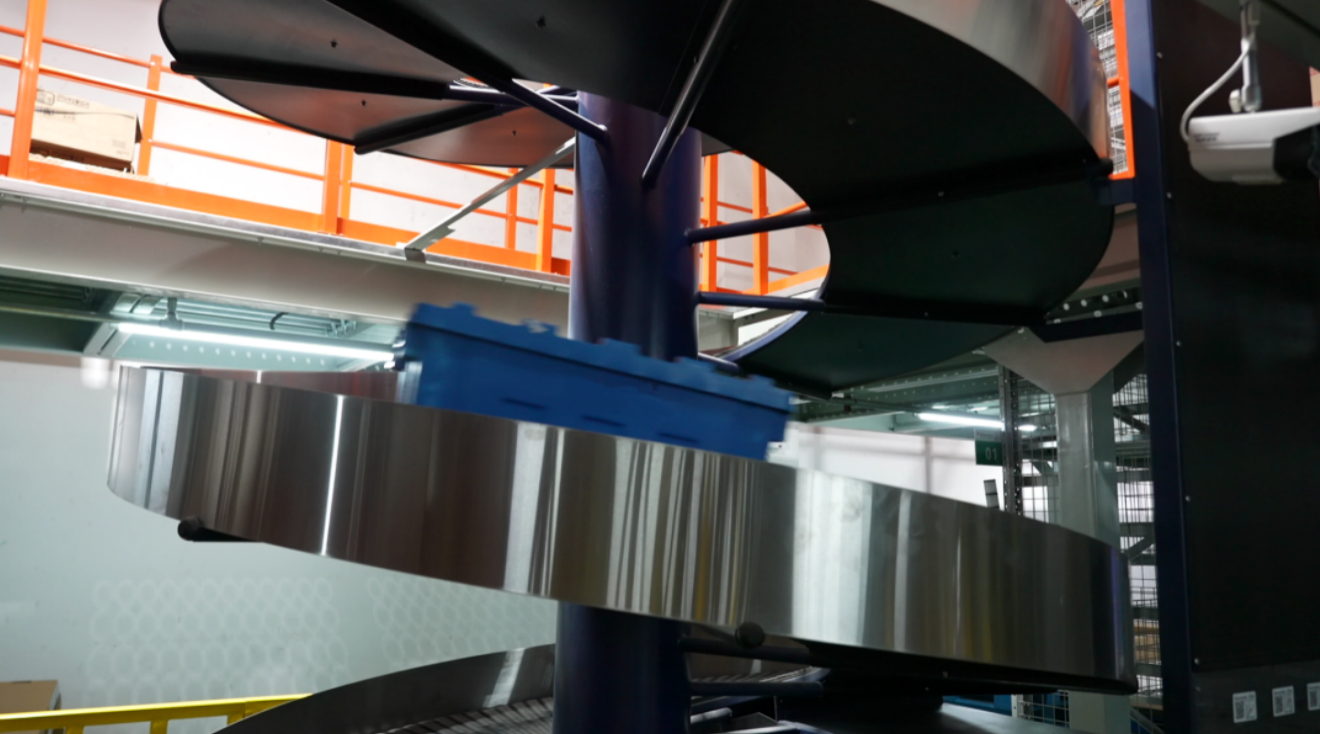

The AS/RS automated warehouse is approximately 96 meters long, 29 meters wide, and 24 meters high, with a total area of about 2,800 square meters and 9,936 pallet positions. It includes a manual online picking area to meet the needs for full-case dispatch and restocking, with a pallet in-and-out conveyor line efficiency of 280 pallets per hour. The solution makes full use of vertical space, combined with automated equipment such as stacker cranes, conveyor lines, and spiral elevators, significantly saving labor and reducing the intensity of manual work.

High Speed

Higher Break-bulk Storage Efficiency

Prolog designs the shuttle garage area according to the break-bulk storage requirements for different categories, with a total of 13,728 storage positions, a flow rack area with 2,112 storage positions, and a shelf rack area with 7,560 storage positions, totaling 23,400 break-bulk storage positions. The shuttle garage features 4 lanes, with 4 goods-to-person picking workstations, 4 shuttle car elevators, 8 cargo elevators, and 16 shuttle cars. The in-and-out conveyor line efficiency is 1,144 boxes per hour. Since the project went live, it has efficiently met the customer's break-bulk picking requirements.

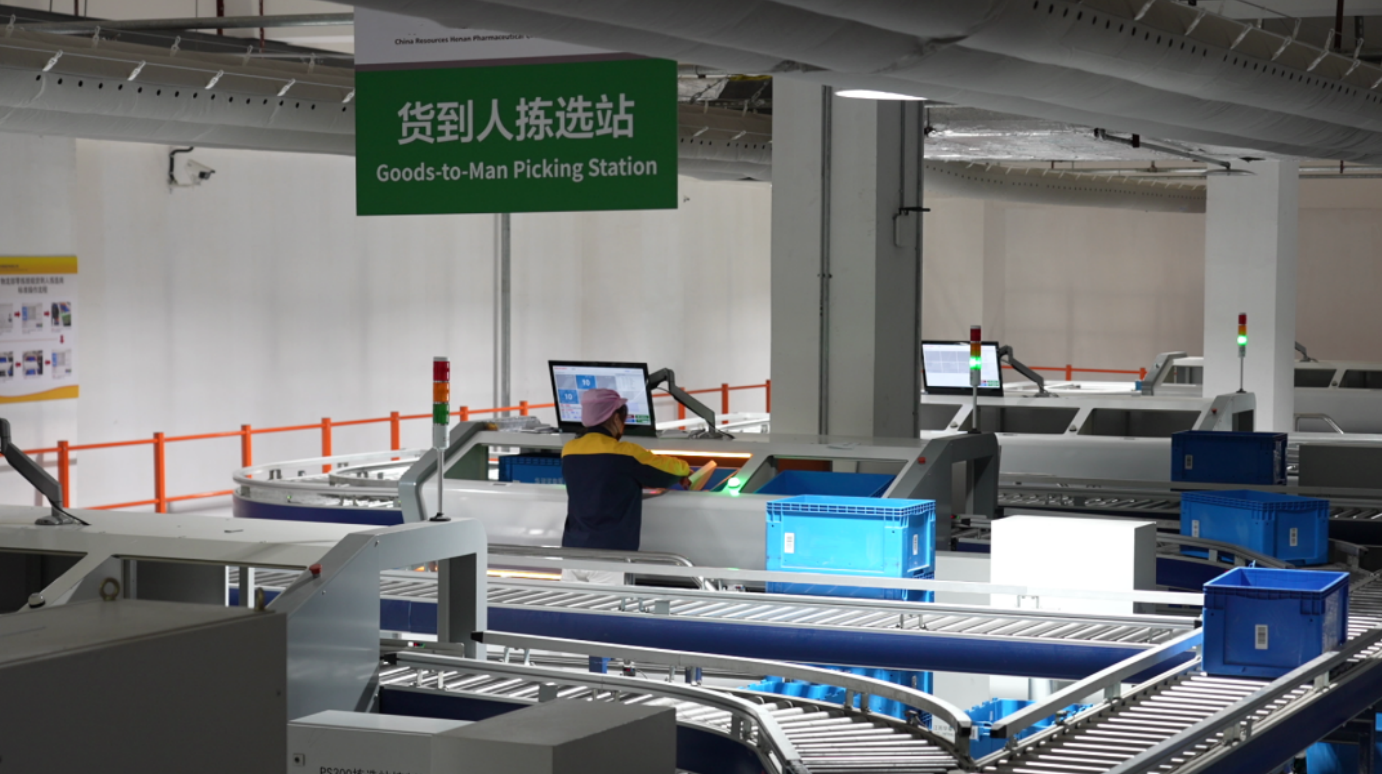

"Goods-to-Person" Picking

Enhancing the Efficiency of Picking Operations

Prolog has introduced the "goods-to-person" picking model for this pharmaceutical distribution company, with a total of 13,728 storage positions, making it the first company in the province's pharmaceutical industry to adopt this model. Under this model, the walking distance for picking and inventory operations is virtually zero, significantly reducing labor intensity. The picking speed can reach up to 280 pallets per hour, which is 3 to 4 times faster than traditional paper-based picking and RF picking. Additionally, this model offers higher accuracy, with picking errors controlled within one in ten thousand. Based on the pharmaceutical company's future sales volume of 30 billion, adopting "goods-to-person" break-bulk picking can save 6-9 workers, resulting in annual labor cost savings of nearly one million yuan.

Three-Flow Integration

Rapid Outbound Processing

The outbound sorting temporary storage area has a total of 376 pallet positions, and the high-speed sorting machine is equipped with 10 sorting chutes, with a sorting efficiency of 5,000 boxes per hour. The entire case outbound from the AS/RS automated warehouse, entire case outbound from the high-bay racking and ground stacking area, and break-bulk case outbound all merge into the high-speed sorting machine. They are allocated to chutes for outbound processing based on routes or customers, meeting the timeliness requirements of orders from different channel customers such as hospitals, pharmacies, and end-users.

Independent Cold Storage

Safe and Reliable

To meet the requirements of GSP (Good Storage Practice) and ensure the safety of consumer medication, the pharmaceutical distribution company has established an independent cold storage facility to ensure the stability of special drug properties. The cold storage mainly includes several major areas: refrigerated product storage area, freezer, break-bulk operation area, outbound temporary storage area, and inbound temporary storage area, with a total volume of approximately 20,000 cubic meters.

As a leading company in the pharmaceutical distribution field, the enterprise, in collaboration with Prolog, has taken the lead in completing the intelligent upgrade of its logistics center, becoming a benchmark for modern intelligent warehousing in the domestic pharmaceutical industry. This upgrade not only achieves energy conservation and efficiency enhancement for the company itself, improving its core competitiveness, but also provides comprehensive services for patients, medical institutions, governments, and suppliers. It has d an open platform that covers the entire chain, including pharmaceutical marketing, logistics distribution, and supply chain-related services, effectively ensuring the supply of medical equipment and actively taking on social responsibilities.